History of the Austin 8

The main source for the content below is from "The Austin Times" from February/March 2006, and was published with permission from and thanks to author Martyn Nutland.

The last years of peace were the most dynamic at Longbridge since Herbert Austin designed and launched the Austin Seven. Leonard Lord was at the helm and amongst his ambitions was the complete rejuvenation of the car range. It is perhaps fitting the outcome has been dubbed the ‘Lord Look’, most notably typified by alligator bonnets and a chrome grille that was pure Buick, hence the Austin 8 was called the little Buick from Longbridge.

At the opening of the Berlin Motor Show on 17 February 1939, the Austin stand was minus any example of the Eight. The visiting German Chancellor, one Adolf Hitler, viewed the Austin stand and asked, “what have you done with the Seven?” Hitler’s first car had apparently been an early example of the Austin Seven, most probably it was a BMW Dixi, which was manufactured with licence of The Austin Motor Company. On the release date for the Eight, 24 February 1939, three examples were placed on display.

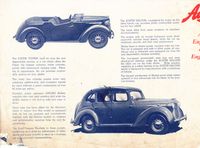

Initially there were to be just four base models. The Eight was to be produced as a two-door saloon, four-door saloon, tourer and light delivery van. For the first time since the early years of the decade, un-named and known simply by their RAC horsepower ratings, plus the prosaic code that would not have been familiar to many outside the industry and trade. Austin 8 or Austin 8HP, with the following model range in 1939.

- AR Austin 8 four door six light saloon.

- ARA Austin 8 two door four light saloon.

- AP Austin 8 tourer

- AV Austin 8 delivery van

The Eight and Ten made it comfortably to the showrooms before war was declared, the Twelve just squeaked in, and the Sixteen didn’t happen until after the armistice.

Most would agree that of the quartet there were two stars and two ‘also rans’. The Austin Ten was hugely successful and the Sixteen was an outstanding family car giving high performance and exceptional value for money. The Twelve was a wimp – fine if you didn’t want to go very far, very fast – and the Eight has been overshadowed by almost everything. Yet, in this latter case, such a judgement is not really fair. The AR Eight – AS1 when it was reintroduced post-war - was the car that revolutionized the little Austin, and although it was superseded, after a relatively short time, by the overhead valve A40 (1947), and the rather more comparable A30 (1951), it was the model that brought Longbridge’s small car thinking up to date.

The significance of this should not be under-estimated. By 1939, the year the Eight was launched that February, the Austin Seven was hopelessly out-dated, out-classed on almost every count by the Morris Eight, and trading on its reputation some mechanical elements of which dated back to WWl.

Certainly, the Big Seven moved the game forward. Whether or not this vastly under-rated, but short-lived model (1937-1939) was ultimately intended as a replacement for the Ruby Seven is a matter for conjecture. The reality is the two cars were marketed and promoted as complimentary. The Big Seven used the ‘ordinary’ Seven’s chassis and suspension layout and had its semi-Girling braking arrangements. But there was an entirely different engine in Austin’s, and the volume production industry’s mode of the day – combined cast iron mono bloc and crankcase with a pressure fed crankshaft mounted in three shell bearings, driving the camshaft by chain and sprocket at one end and a flange mounted flywheel carrying a conventional clutch at the other.

But it is a fast, yet often quoted, misconception, that the Austin Eight adopted the Big Seven engine. As has been explained in these columns the latter’s engine is markedly different yet a step forward from the Seven in the modernization process. Without repeating what has been said before, the Austin 8 has a different crankshaft and connecting rods, the entire lubrication system from sump pan to pump is different and the detailing of the valve gear has also been altered as has the manifolding, cooling and even the components for mounting the unit.

That said, the Eight does have a 900 cc (56.77 x 89 mm) side valve engine (the Big Seven’s stroke is 0.1 mm shorter because of a smaller diameter for the big end journals). The power output is a tad mysterious though. When the early literature was published, 27 bhp at 4,400 rpm was quoted which was a slight improvement over the Big Seven’s 25. Indeed the valve events had been changed to allow the Eight’s inlet to open five degrees before top dead centre as opposed to tdc for its predecessor. However, one suspects some massaging of the figures as that quoted for the Eight soon settles at 24 bhp for the same revs! The mystery is further compounded by the earliest literature quoting the Big Seven’s fractionally smaller dimensions and showing an amalgam of engine features. For instance, the Eight’s hollow, barrel, tappets as opposed to the solid type fitted to Big Seven’s, but the latter’s elegant aluminium fan as distinct from the composite steel affair.

Eights sport, and the drum pattern AC oil wetted air cleaner of the ‘Seven’ as opposed to the horizontal, cylindrical type, mounted at an angle across the engine bay’s left side and usually fitted to the Eight. So perhaps there were pre-production, or even very early customers’ cars that ran on partially converted Big Seven engines. Certainly items like the tappet barrels could have been changed very simply by removing the bronze guide for the Big Seven’s (and Seven’s) solid type. But of rather more interest than this wholly conventional engine is the ‘chassis’. Austin made their first move toward monocoque and adopted the same principles for the GR1 Ten introduced in May. The Twelve would retain a traditional cross-braced girder frame that after the war would be adopted by the Sixteen.

The Eight broke new ground though with a steel platform that had box section side members open on the outward facing side so that when the body, which could still be detached, was fitted, it formed box sections. There were also transverse, boxed cross members - at the front and a little, further back to support the rear of the engine, two more, integral with the floor ‘pan’ beneath the front seat runners and another substantial one at the rear of the platform. In addition the side members formed ‘arms’ or ‘pontoons’ extending ahead of the interior platform, met up with the front cross piece, and added further rigidity to the structure. As the brochures said of this ‘outstanding investment’ the ‘special chassis and floor is a complete welded unit giving diagonal stiffness, and the body sill is bolted to the frame at numerous points, forming a box section. The front portion of the frame and the cross members are completely boxed and the front portion is also diagonally braced. Its lateral and diagonal rigidity and great strength play an important part in providing good road-holding; the centre of gravity is low and yet there is good ground clearance.’

It is interesting the writers are loath to depart from traditional terms with which the Austin customer would be familiar – chassis, frame, diagonal bracing. None of which was really there yet the impression was there was nothing new fangled or ‘Continental’; viz-a-viz Citroën, perhaps! The road holding was enhanced by a normal suspension ‘package’. Gone were the Seven and Big Seven’s archaic transverse front spring and quarter elliptic rears in favour of semi elliptics all round. These were nearly 40 ins long at the back and under-slung and nearly 29 ins in length at the front.

Either Luvax or Armstrong double acting hydraulic shock dampers were used all round but at the front they were mounted transversely so the arms were parallel to the axle beam. The links changed subtly over the years. Very early output having ends curving through the bushes and later production a spherical attachment. The transverse ‘damper’ layout was intended to act as an anti-roll device and the Twelve and Sixteen actually did have anti-roll bars.

Steering was, at first by ‘hour glass’ worm, and sector, with the gearbox ahead of the radiator and the side tube working back to a track rod mounted in front of the axle. Later cars had a Bishop cam T-Type system with the commendable feature of a variable ratio to reduce driver effort for close range manoeuvring.

Other modernities were the use of Silentbloc bushes where appropriate. Longbridge were obviously proud of the car’s handling as one of their delightful publicity films features an Eight exclusively, storming successive passes during a day in the English Lake District. The model copes well, of course, but on celluloid has a tendency to look like a mouse on a hotplate! The Eight had a four speed gearbox with synchromesh on second, third and fourth. Overall ratios were 21.88:1 on first then 13.22, 8.31 and 5.43:1 respectively.

The A30 eventually inherited a version of this ‘box, and when so applied it proved one of the ‘New Austin Seven’s’ weakest features! There was a dry single plate clutch that removed the fierceness for which, depending on your view, the original Seven, and to some extent the later models and Big Seven, were either famed or notorious. The old torque tube transmission went, in favour of a totally conventional open shaft with universal joints at each end and lifted straight off the shelf at Hardy Spicer’s in Birch Road, Whitton.

The rear axle was a three-quarter floating design of the ‘banjo’ type unlike the three piece unit of early Sevens and the ‘D’ pattern of later cars and the Big Seven. Used now with splined axle shafts this meant the crown wheel and differential gearing could be removed as a unit facilitating adjustment or repair.

Like the exterior of the car the interior was modern and pleasing to the eye. The instrument board was that of the Sixlite Big Seven (the two-door Fourlight had a different layout altogether) and all other Austin models of the day. It incorporated a Smiths speedometer with dark brown letters on a cream chapter ring and a matching dial with a cluster of gauges (ammeter, fuel and oil pressure clockwise from the top) was placed directly in front of the driver. The dashboard itself was a pressed steel fitting with a mock wood grain effect. The steering wheel was steeply raked but gave a comfortable and purposeful driving position. Most factory illustrations show the wheel with three solid spokes but most if not all production model had a sprung wheel same as the rest of the range. There were carpets front and rear but as on the Ten these were not fitted over the gearbox which was concealed by a rubber moulding with the gear positions in relief.

On the ‘sunsine saloons’ there was leather upholstery for the seats. Pre-war the driver’s had a trigger adjustment and the front passenger’s could be relocated by fiddling with clips underneath the tubular frame. Post-war car’s had proper adjustment for both seats. They also had a rear window blind controlled by ring and string pull from the command module and a sun visor which you didn’t get pre-war unless you chose the model with the sliding roof. You did get an interior roof-light however.

Outside there were self-cancelling trafficators running off the six volt electrics and chrome bumpers, but no over-riders, which is an easy and quick way to tell an Eight from a Ten from the front! Indeed at the back the bumper only protected the quarters and another dead give-away when viewed from the rear is the Eight’s single pane window. The Ten has a divided one as on the Twelve and Sixteen. Reverting to bumpers for a moment, the pre-war cars could be lifted by attaching a ratchet operated jack to the bumper bracket at the relevant corner. Post war cars had a trap ‘door’ on either side forward of the front seats through which a Stevenson’s telescopic jack was lowered and operated with the wheel-brace. The van had a screw jack hand-me-down from the Seven.

The little Eight was just over 12’ foot long overall and 4’ 8” wide and when it was launched there were six options. The most basic was a two door saloon (Fourlight Saloon) without a sunshine roof and costing £128 - £139 with - model code ARA. For the same £139 you could have had instead a four door (Sixlight Saloon) with a plain roof or one with a sunshine roof for £149. The four door model code was AR. Unusually, by today’s standards, something a little bit more exotic was, with one exception, cheaper. A lovely two door tourer cost £132 and a whole ten shillings, and its four-seat counterpart a round £135. They came with a hood and side curtains the latter being stowed when not in use in a special rear compartment. The windscreen folded flat and there were cutaways to the tops of the door so hairy drivers could jump in if they wished!

There was also a pretty little 6 cwt delivery van, Type AV. These cars are very rare today. The van had a body capacity 82 cu. ft. which was able to carry up to 6 cwt. It was advertised with you buy a van - but you invest in an Austin. The price was £120 for a grey primed van and for £3,10,0 it was painted to standard colour.

The body shells were the same but on the two seater the rear seat was replaced by a large, flat, luggage platform making the model ‘very attractive for touring’. The code was AP.

Colours for the saloon cars were blue, black, maroon and grey and the same for tourers except blue was deleted. Production of the Austin 8 cars ceased for the duration in 1942 and of the van in 1940. By then about 46,400 had been made. A proportion of those would have been for military use – some saloons, some two-seater tourers. The latter were outwardly distinguishable from the civilian version in that they had two large, near-vertical louvres in the scuttle instead of the chrome embellished horizontal slit in the bonnet side panel. The wheels were also of a disc type without the perforations of the peace time cars and the front registration plate was often above the bumper bar instead of below it. Most probably the only difference to the engine was that the coolant inlet on the right side of the block was cast steel and not aluminium. But there may have been other detail changes. More information related to the Austin Eight military tourer, can be found on the Military tourer section on this web page.

Apart from Austin Eight vehicles commissioned by the armed forces their engines found a variety uses. These included use in the Beresford Stork portable fire pump and of course, for the airborne lifeboat where they had a dubious reputation amongst ‘the powers that were’. Other appearances were as the machinery for merchant ship lifeboats where they adopted the model name, Thetis, as applied to Austin Seven marine engines since the mid-1930s. Marinization took the usual form of major modifications to the cooling and lubrication systems, the application of a wet plate clutch and adoption of magneto ignition the latter also being fitted to the stationary engines.

Production of the Eight car and van recommenced in August 1945, but there was now only one private version – the four door saloon re-coded AS1. The van was AV1. Numerically the model was Austin’s most successful car of the post-war era, out-stripping even the Ten with sales between 1945 and withdrawal in 1947 of some 56,000 - 500 more than the larger model. The price though was now well over £300! The marketing of any car is fascinating and the Austin 8 no exception. There was nowhere much for the company to place the Seven other than as mobility for the masses or ‘introductory’ motoring. By the time the Big Seven came along the customer for economy cars was much more sophisticated and that model was positioned rather differently – perhaps too much so.

The model codes for the post war eights were:

AS1 = Austin 8 four door six light saloon.

AV1 = Austin 8 van.

Austin Eights in Australia

Casual talk of full Australian car manufacture was first raised by Prime Minister Bruce in 1927. In 1930, the Scullin government introduced tariffs on imported motor vehicle mechanical parts, such as gears, axles, bearings and motor parts. By 1937 nearly half the factory cost of motor vehicles in Australia was attributable to local content; by 1939, 40 per cent of replacement parts were manufactured locally. In December 1939, the government entered into an agreement with Australian Consolidated Industries (ACI) for the production of vehicles; based on 1938 legislation, the agreement enabled the payment of a bounty on the production of each engine as well as protection from foreign-owned competition. The Motor Vehicles Agreement Act 1940 gave ACI practically exclusive rights to manufacture chassis and engines in Australia. The combined effect of the Motor Vehicles Agreement Act and the Bounty Act was to prohibit companies with less than two-thirds Australian ownership from building engines or chassis. Due to the outbreak of the World War ll, ACIмs output never developed to the intended level of full production.

Before the war ended, the government recognized the need to assist industry to move from wartime production to civilian production and established the Secondary Industries Commission within the Department of Post-War Reconstruction. The Commission was instrumental in having the ACI Agreement and the Bounty Act repealed, allowing foreign-owned companies to establish chassis and engine works, and paving the way for the construction of complete vehicles. The Department of Post-War Reconstruction wrote to every known manufacturer and assembler of motor vehicles and motor vehicle components, seeking to establish the state of their development, their plans for future production and their desires for government assistance. The Department was prepared to offer financial assistance and tariff protection to assist a company to manufacture entire vehicles in Australia.

Although the post war production of the two door four light saloons and the open tourers were not continued in UK, you will find post war Australian 8 tourers, build by Ruskin, Larke Hoskins and Richards, for the reason mentioned as above. There are even two door post war doctor coupe's known build by Ruskin. The Australian Larke Hoskins Austin 8 tourer was called the WASP. The Richards tourers were recognized by the curved cease on the doors. The chassis numbers for some of these cars are AS1 which is the post war indication for the four door six light saloon, which means the Australian tourers are not indicated as AP. Also the Australian Tourers are slightly different from it's original pre war UK model. The seats are different and also the front wind shields are slightly different. Some of the Australian tourers even has a trunk lid, a nice addition, which was missing on the pre war 8 tourers.

Production numbers

From the total of about 103,585 Austin Eights produced only about 1% is still in existence today. The post war four door six light saloon is most produced and therefore the model you will find in existence the most. The pre war versions are rarely found any more. More information about how many Eights have survived can be found on the Austin Eight Register page of this web page. Austin Motor Company published manufactured figures from August - July. Below the records for the amount of Austin Eights manufactured from 1939 - 1948. The last pre war chassis manufactured was 47.600.

Year (Aug - Jul) | Austin 8HP manufactured / year | Austin 8HP manufactured / total |

1938 - 1939 | 17,447 | 17,447 |

1939 - 1940 | 24,230 | 41,677 |

1940 - 1941 | 5,064 | 46,741 |

1941 - 1942 | 707 | 47,448 |

1942 -1943 | 34 | 47,482 |

1943 - 1944 | 0 | 47,482 |

1944 -1945 | 0 | 47,482 |

1945 - 1946 | 15,169 | 62,651 |

1946 - 1947 | 31,619 | 94,270 |

1947 - 1948 | 9,315 | 103,585 |